Machine introduction:

Premade bag packing machine, also known as Doypack Packing, is a highly automated device designed for product packaging using pre-made bags. In modern factories that pursue automation and efficiency, a suitable premade bag packing machine can significantly improve the production capacity, stability, and hygiene standards of the packaging process. Foshan SUK is deeply involved in the field of automated packaging and is committed to providing factories with the most suitable and efficient premade bag packaging solutions.

https://www.sukmachinery.com/product/premade-bag-packing-machine

- 1. Premade bag packing machines automatically complete bag picking, bag opening, metering and sealing.

- 2. Composite film and aluminum foil can be used as bag materials. Four-sided sealing, stand-up pouches, zipper bags and other bag types are all acceptable.

- 3. Can pack granules, powders, lumps, liquids/pastes. Accurate metering ensures consistent product weight. Complies with hygiene requirements for the food, pharmaceutical and other industries.

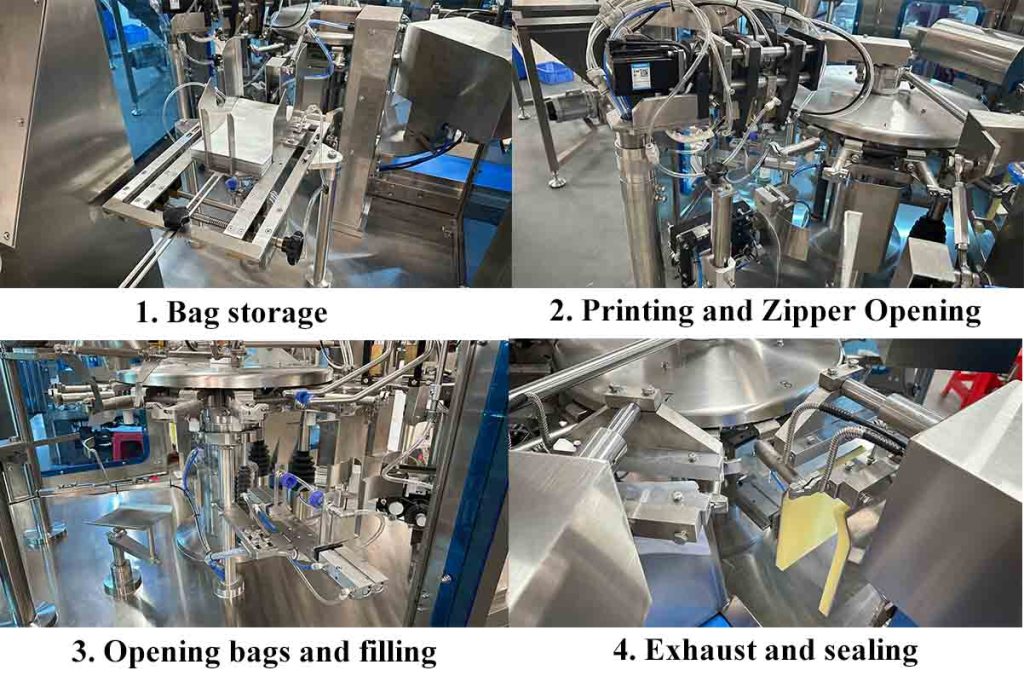

Core Structure Analysis:

- 1. Bag Storage Bin: Orderly storage and automatic separation of pre-made empty bags. The design is reasonable, ensuring smooth bag retrieval without jams; the capacity is sufficiently large, eliminating the need to stop the machine to add bags.

- 2. Printing and Zipper Opening (Optional): Prints production dates, batch numbers, and other information on the bag body; printing is clear, stable, and precisely positioned; for bags with zippers, the zipper is automatically and accurately opened.

- 3. Bag Opening: Utilizes suction cups, air blowing, or robotic arms to precisely and reliably fully open empty bags, preparing them for filling. High bag opening success rate, compatible with bags of various sizes and materials, is critical for ensuring smooth subsequent processes.

- 4. Filling: Uses various metering devices such as screws, measuring cups, weighing scales, or liquid pumps to fill products into the opened bags. Typically, filling is done to 90% capacity to ensure a secure, aesthetically pleasing, and well-sealed closure.

- 5. Sealing: Perform heat sealing. The sealed surface is flat and wrinkle-free.

Wide Applications:

- Food Industry: Expanded foods, pet food, coffee beans/powder, roasted nuts, candies/chocolate, frozen foods, seasonings (powdered/granular), tea, baking ingredients, etc.

- Personal care industry: Fragrances, laundry detergent (liquid/powder), dish soap, shampoo, shower gel (small packets), wet wipes, face mask powder, etc.

- Pharmaceutical/health supplement industry: Traditional Chinese medicine slices, granules, powdered supplements, tea bags, disinfectant powder, foot bath packets, etc.

- Chemical industry: Fertilizer seeds, dyes/pigments, additives, plastic pellets, cleaning agents (powdered), etc.

- Hardware/Industrial Products: Screws, nuts, small parts, solder paste, lubricating grease, etc.

Bag Type Selection:

- Four-sided sealed bags: Sealed on all four sides for a more square and three-dimensional appearance.

- Stand-up pouches: With a folded corner or flat bottom, they can be placed upright for good shelf display.

- Zipper pouches: The bag opening has a zipper that can be opened and closed repeatedly for easy access.

- Special-shaped pouches: Specially shaped pouches customized according to specific needs.

Frequently Asked Questions (Q&A)

Q: How much can a premade bag packing machine save in costs compared to manual packaging?

A: One machine can replace multiple workers, reducing labor costs. Accurate feeding reduces waste, improves efficiency, stabilizes quality, and reduces rework and losses caused by human error.

Q: What are the core parameters of a premade bag packing machine?

A: The packing speed determines the production capacity. The length and width of the bag type and the weight of each bag. The feeding accuracy and method depend on the characteristics of the material. The sealing method and effect. Foshan SUK engineers will recommend the most suitable machine configuration based on your specific needs.

Q: Is it troublesome to change the machine to produce different products or bag types?

A: Premade bag packing machines are designed with a focus on modularity and convenience. Changing the bag type usually only requires adjusting the bag storage and bag clamping device. Changing products mainly involves adjusting or replacing the feeding device (such as screws and measuring cups). Skilled operators can complete the changeover in a short time. Foshan SUK Equipment provides detailed operational training and optimizes the changeover process.

Choose Foshan SUK to inject efficient packaging power into your factory! Purchasing a premade bag packing machine is a key step in improving factory automation and competitiveness. Foshan SUK has rich industry experience, mature technical solutions, and a comprehensive after-sales service system, and is committed to providing you with the best service.Contact Foshan SUK now to get a premade bag packing machine solution tailored to your factory! Let us help your packaging process run efficiently and win in the future!

- 📧 Email: [email protected]

- 📱 WhatsApp: +86 136 9058 8270