Introduction to stick packing machine:

The stick single-row clamp-pull packaging machine is an automated packaging equipment designed for powder, small particles, liquids, pastes and other products. It uses prefabricated roll film and a unique clamp-pull mechanism to achieve sealing at both ends. It is specially designed for long and narrow products (5-20cm in length), prevents material jamming, and provides stable transportation. Heat sealing at both ends + clamp-pull in the middle provides strong sealing, preventing leakage or oxidation of the contents. It reduces manual intervention and roll film waste. A variety of cut-off methods and packaging bag types are available to choose from, enhancing the appearance of the product.

https://www.sukmachinery.com/product/stick-packing-machine

In industries such as snacks, daily chemicals, and pharmaceuticals, the efficient packaging of strip-shaped products (cheese sticks, mouthwash, pet food, honey sauce, coffee sugar) has always been a production pain point. Traditional equipment is prone to jamming and poor sealing, while manual packaging is inefficient. Foshan SUK's stick packing machine is designed to solve the problem of automated packaging of long and narrow products, achieving high-speed, stable, and strong sealing, providing solid support for factories to reduce costs and increase efficiency!

Core structure analysis of the stick packing machine:

- 1. Roll film conveyor system: controls the smooth stretching of the roll film, positions the roll film with color marks to ensure pattern alignment, and supports composite film/aluminum foil and other materials.

- 2. Bag forming machine: folds the flat film into a U-shaped bag, with a customized guide groove design that perfectly matches the cross-sectional size of the stick-shaped product.

- 3. Product Dosing Mechanism: Different dosing mechanisms are selected based on material properties. For powders, a screw feeder or vacuum conveyor is used. For granules, a measuring cup or electronic scale is used. For liquids, a liquid pump is used.

- 4. Longitudinal Heat Sealing Mechanism: Seals the back seam of the film to form a tubular structure, ensuring a flat, wrinkle-free seal.

- 5. Clamping and sealing unit: Pneumatic clamps horizontally secure the film, while the heat sealing knife simultaneously seals both ends. The middle section is pulled to form a “clamping and pulling” three-dimensional packaging, enhancing sealing performance and compression resistance.

- 6. Cross-cutting and output: A knife cuts individual packages, and a conveyor belt smoothly outputs them.

Key application industries and material types

- Snack foods: honey, coffee powder, white sugar, cheese sticks, tomato sauce, pet meat sauce

- Personal care products: mouthwash, soap bars, trial-size shampoo, small-packaged shower gel

- Pharmaceuticals and health supplements: traditional Chinese medicine ointments, probiotic bars, powdered beverages, sports energy powders

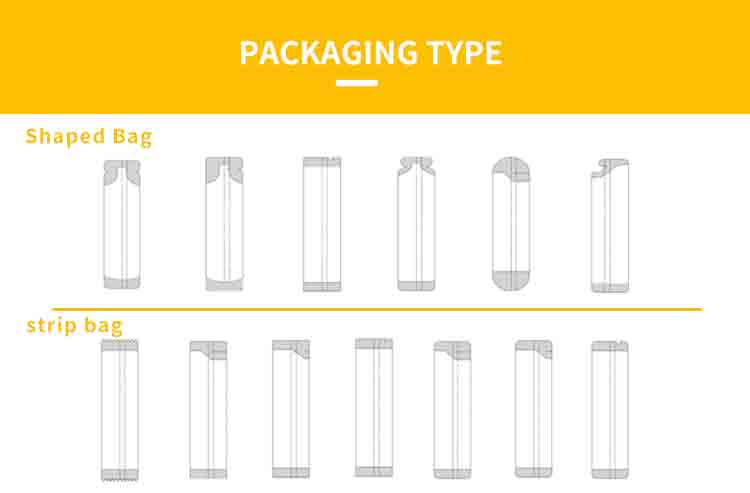

Diverse bag type requirements:

- Back-sealed zipper bags: Basic bag type with a vertical seal on the back and zipper seals on both ends, economical and practical;

- Three-sided sealed zipper bags: With additional seals on both sides, suitable for easily leaking pastes/liquids;

- Custom-shaped zipper bags: Custom molds support creative designs such as square bottoms, rounded corners, and curved contours;

- Easy-tear design: Pre-cut tear lines at the zipper seals to enhance user experience.

- Note: Corresponding bag-making molds are required, and Foshan SUK provides customized services.

Packing machine focus Q&A:

Q1: What is the difference between clip sealing and traditional end sealing?

A: Traditional sealing is only heat-pressed, while clip technology simultaneously stretches the film horizontally during sealing, allowing the packaging film to tightly wrap the product, improving sealing by 50%+ and blocking water vapor/oxygen. This reduces the amount of air inside the film and prevents the product from shaking and breaking during transportation.

Q2: Is the equipment compatible with strip products of different lengths, widths, or cuts?

A: It can be quickly switched, but only within the range that the machine can complete. Foshan SUK equipment uses a modular design, and the bag maker can be replaced to change different cross-sectional sizes. The bag length can be adjusted by adjusting the color mark on the screen. The sealing shape and method can be changed by replacing the cutting knife.

Q3: Stick products are prone to jamming during feeding. How can this be solved?

A: Choose the right feeding method and send us sample information or materials in advance for evaluation.

Why choose Foshan SUK stick single-row clamp pull packaging machine?

Deep cultivation of the packaging machine industry: 100+ successful cases, proficient in food/daily chemical/medical industry packaging standards;

A variety of fully automatic packaging machines to choose from, as long as you have bulk packaging needs, we can provide it.

Cost-effective solutions: From single machines to entire lines, SUK is dedicated to achieving fully automated packaging.

Full cycle service: Whether you are an end-user factory or want to sell our packing machines locally, you can contact us at any time, and we will provide comprehensive support and service.

- 📧 Email: [email protected]

- 📱 WhatsApp: +86 136 9058 8270