Machine Summary:

In response to the refined packaging needs of the global powder industry, the selection of a powder packaging machine directly affects production efficiency and product value. Foshan SUK provides an in-depth analysis of the technical characteristics and cross-industry applications of the three mainstream machine types—vertical packaging machines, premade bag packing machines, and stick packaging machines—to help companies accurately match international market demand.

https://www.sukmachinery.com/product/stick-packing-machine

https://www.sukmachinery.com/product/suk-vertical-packaging-machine

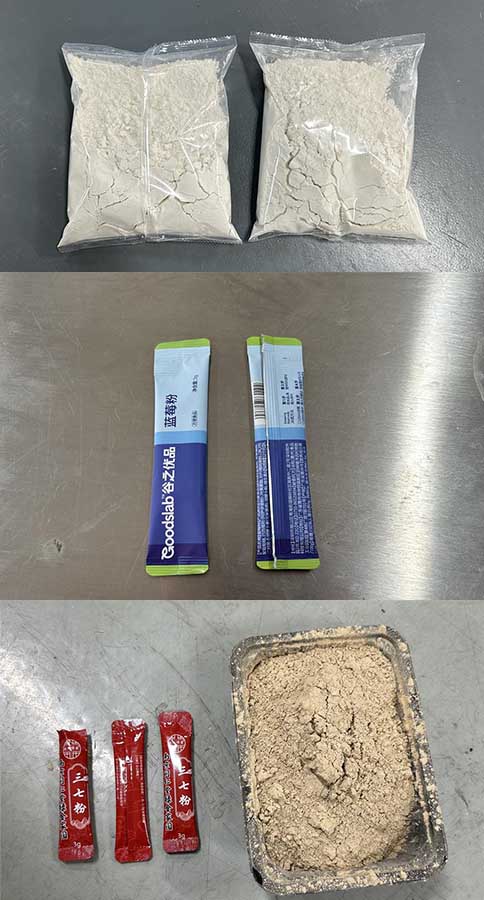

Powder packing machine model table

| Packaging Type | Compatible Models | Typical Specifications | Accuracy Control |

| Standard three-sided sealed bags | Vertical powder packing machine | 5g-5kg | ±0.5-1% |

| Irregularly shaped pre-made bags | Premade bag packing machine | Stand-up pouch/zipper bag | ±0.2-0.5% |

| Tubular portable packaging | Stick packing machine | 1-20g suction stick | ±0.3% |

Technical analysis of SUK's three major machine models:

1. Vertical powder packaging machine: high-efficiency continuous operation

Screw metering system, dust-proof sealed design. Production capacity of 20-60 bags/minute. 304 stainless steel contact parts. Suitable for packaging: milk powder, seasoning powder, small bags of chemical powder, and other free-flowing powder packaging.

2. Premade bag powder packing machine: high-precision pre-made bag packaging

Screw metering or vacuum powder feeding system. Can be used with zipper bags, stand-up pouches, and four-sided sealed bags. Can be used for quantitative packaging of medicinal powders, nanomaterials, baking powder ingredients, and high-end food powders.

3. Stick packing machine: portable packaging expert

The stick packing machine, also known as the stick packing machine, is specially designed for portable packaging. Milk powder, coffee powder, probiotic powder, seasoning powder, etc. Vertical roll film tube making technology is more stable. Add a dust collection device to prevent powder spillage.

Five core elements for model selection:

Material characteristics: Poorly flowing powders require a vibration aid device (such as coffee powder), and static-sensitive powders can be equipped with an ion wind bar (such as metal powder).

Production capacity requirements: Fully automatic powder packaging machine (20-60 bags/minute)

Packaging accuracy: ±0.1g

Machine standards: The contact surface is made of 304 stainless steel, which meets the packaging requirements for food and medicine.

Extended functions: Multilingual operating interface. Equipped with a coding machine to print the production date in real time.

Powder packaging machine (Q&A)

Q1: How can the accuracy of 1-5g micro-metering packaging be ensured?

SUK solution: bag feeding + precision screw system, with an average error of ±0.1g measured over 10,000 bags.

Q2: Can it be compatible with multiple bag types?

The machine can be adjusted to accommodate different bag types, and our sales team will understand your packaging needs in advance.

Q3: How to deal with powder spillage?

SUK's patented technology creates a closed structure at the small material inlet.

Summary and action guidelines

The selection of a powder packaging machine is essentially based on material characteristics, packaging form, and production capacity requirements. Vertical packaging machines are the basis for continuous production packaging lines with the best cost performance. Premade bag packing machines are the choice for high value-added products. Stick packaging machines: more packaging bag types and sealing options.

Foshan S U K Foreign Trade Service Advantages:

Global case verification: equipment exported to 56 countries, adapted to different climatic environments.Professional production factory: providing global distributor services, we help you occupy the local packaging market at the lowest price.Leave your contact information now to get an exclusive powder packaging machine solution and export quotation!

- 📧 Email: [email protected]

- 📱 WhatsApp: +86 136 9058 8270